Has been the leader in the design and manufacture of tilt-pad fluid film thrust and journal bearings for all types of rotating machinery with hundreds of installations. The load in a Kingsbury bearing is carried by a wedge-shaped oil film formed between the shaft thrust-collar and a series of stationary pivoted pads or segments.

Fluid Film Bearing Features For Clearance And Lubrication Kingsbury

For Kingsbury thrust bearings to operate safely and efficiently continuous self-renewing oil films must be present between the shoes and collar.

. A simplified theoretical model governing the. Our equalizing thrust bearing actually transmits the load through a self-. Kingsbury has adapted its Leading Edge Groove lubrication technology to a new low-profile design.

A 6x6 or 8x8 designates a bearing with that number of shoes on both sides of the collar. In order to understand the air lubrication behavior of Kingsbury thrust bearing demonstration an experimental and theoretical investigation on a simulated Kingsbury thrust bearing was presented. The oil feed system includes a hydraulically actuated piston between the pad and retainer to.

The bearing consists of a thrust runner a down-thrust bearing and an up-thrust bearing as shown in Fig. Since 1912 Kingsbury has gained unequaled experience in designing and manufacturing thrust bearings. The thrust and journal bearings at the inlet end of such a machine are subjected not only to the heat equivalent of bearing friction but also to the heat transmitted from the turbine casing.

In this new model each pad is designed to carry an equal amount of thrust load. An H in the code means a separate collar is furnished by Kingsbury. Up to 3 cash back Kingsbury Thrust Bearings 1957 US Navy Training Film MN-8478.

Although certain products such as equalized thrust bearings have had standard dimensions for many decades other important aspects such as instrumentation have not. Fundamentals Damage Evaluation Repair Pioneer Motor Bearing. A single 6 or 8 designates a bearing with that number of shoes on one side of the collar only.

1211B for the positive barrier or bag seal type. The thrust bearing location is depicted in Fig. A controlled inlet thrust bearing that features a cool oil cavity for the pad entrance oil along with a hot oil carryover director and wiper is discussed.

The company is handles critical applications with leading thrust- and journal-bearing technology. The motions of the thrust disk and tilting pads were measured by eddy current sensors for three mass load cases. February 2005 1 c 2006 Pioneer Motor Bearing Company Fluid Film Thrust Bearings.

In 1896 inspired by the work of Osborne Reynolds Albert Kingsbury conceived and test-ed a pivoted shoe thrust bearing. On the inactive side there are only 3 pads that sit on two large conical washers see picture overleaf showing this type of thrust bearing. This is because proper alignment of the bearing and housing relative to the thrust collar is difficult and because accumulated manufacturing tolerances.

Originally a public domain film slightly cropped to remove uneven edges with the aspect ratio corrected and one-pass brightness-contrast-color correction mild video noise reduction applied. When the generator was rebuilt for 60-cycle service in 1950 the original Kingsbury bearing was retained as it was in perfect condition. Albert Kingsbury 1863-1944 developed the principle in the course of bearing and lubrication.

Kingsbury thrust bearing this section lists basic bearing elements and how they work as well as design options and accessories. Thrust bearings without spherically pivoted shoes and the equalizing feature of leveling plates have a substantially reduced factor of safety margin compared with Kingsburys EQH design. Design Engineer with Kingsbury In-corporated in Philadelphia Pennsylvania.

It carries a weight of 220 tons. Metallic shoes within the bearing. The pump thrust bearing was a Kingsbury tilt pad thrust bearing of an old outdated design known as a JHN.

The new LEG SlimLine is a fully equalizing thrust bearing with all the attributes of our standard LEG product but in a thinner profile. 14 Bearing Housing Requirements The LEG thrust bearing housing requirements are similar to that of a standard thrust bearing. Kingsbury the test bearings ran well.

A stable bearing design holds the rotor at a As speed increases the oil pressure begins to build up lifting the rotor off the bearing. Prior to joining Kingsbury Inc. Albert Kingsbury invented the hydrodynamic thrust bearing Kingsbury Inc.

This section details design features which we developed to improve your machines performance. Under these severe conditions Kingsbury bearings outper. On the active side of the thrust bearing there are 6 pads which sit on individual levelling plates.

That the pivoted shoe thrust bearing at only 14 the size had 17 the area but operated suc-cessfully with only 110 the frictional drag of the horseshoe bearing. Hydrodynamic Bearing Notebook Flexware Inc 2020 4 As rotation begins the shaft begins to climb the bearing wall with metal-to-metal contact occurring. How Kingsburys Thrust Bearing Works A thrust bearing transmits axial shaft loads into the foundation or machine support of rotating apparatus.

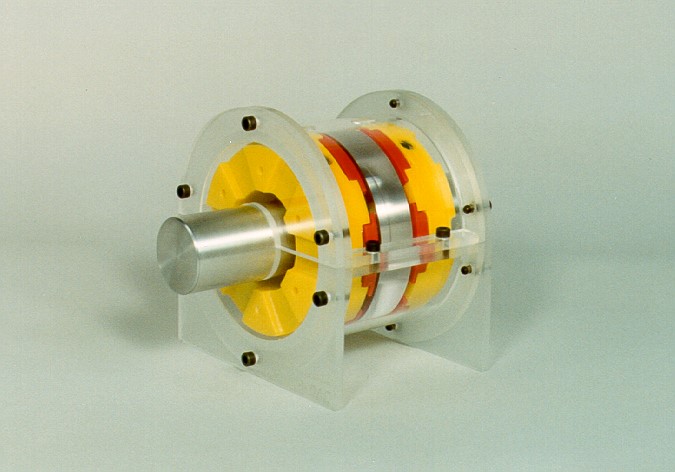

DAC Worldwides Kingsbury Thrust Bearing Model 209 is a plastic facsimile of a Kingsbury fluid film thrust bearing that allows for classroom instruction in the design maintenance and application of fluid film bearings used in industry. The soundtrack was also processed with volume normalization noise reduction clipping. He is responsible for the design analysis development and troubleshooting of fluid-film thrust and journal bearings.

Kingsbury Thrust Bearings Yesterday Today Tomorrow. Similar to a flooded bearing design the lubricating oil must be supplied to the annulus formed between the base ring and housing. In fact LEG bearings may often be retrofitted in place of flooded bearings.

DAC Worldwides Kingsbury Thrust Bearing Model 209 is a plastic facsimile of a Kingsbury fluid film thrust bearing that allows for classroom instruction in the design maintenance and application of fluid film bearings used in industry. Kingsburys four thrust bearing styles are J B E and S. In his 13 years with Kingsbury Inc he has also served as a Service Engineer and Research Engineer.

Kingsbury thrust bearings are used to transmit or absorb significant thrust in mechanical drive applications. This results in an extremely low coefficient of friction and negligible bearing wear. Building a Legacy Since 1912 when Dr.

Kingsbury a manufacturer of products for rotary machinery introduced the six-shoe thrust-bearing design nearly a century ago and its products have provided a model for the rest of the industry to follow ever since. The first Kingsbury thrust bearing ever installed on a hydro-electric generation unit was put into service in this machine on June 22 1912. Kingsbury Bearing Design Configurators Since 2010 Kingsburys Engineering Department has embarked on a project to create or update standard designs for all major bearing lines.

1214The thrust runner is keyed to the seals shaft and its position on the shaft is fixed with snap rings. 1211A for the labyrinth seal type and in Fig. Kingsbury thrust bearings are used to transmit or absorb significant thrust in mechanical drive applications.

Tilting Pad Thrust Bearing With Slimline Design From Kingsbury

Kingsbury Bearing Design Configurators

Tilting Pad Thrust Bearings Design Selections Kingsbury Inc

Tilting Pad Bearing With Leg Design From Kingsbury

Kingsbury Updates Thrust Journal Combination Bearing

Fluid Dynamic Bearing Eqh Style From Kingsbury Bearing Engineering

Kingsbury Thrust Bearing Model In Depth Mechanical Drives Training

Fluid Dynamic Bearing Eqh Style From Kingsbury Bearing Engineering

0 comments

Post a Comment