CN-103046184-A chemical patent summary. The properties of the textured yarn can be altered by changing these parameters.

Drawing Texturing Intermingling And Heat Setting Process

During the process of yarn texturizing a partially oriented yarn is used as feed yarn.

. Is produced by processing POY through a texturing process. Draw texturing is defined as a process when an incompletely drawn feeder yarn is drawn to the intended yarn size and textured in a continuous manner. The so-called false twist is that the yarn is twisted in a certain direction during the subsequent processing and the yarn is still straight when wound.

Thermoplastic filament yarns are used in most texturing processes. The properties of false-twist textured yarns in the aspects of crimp characteristic and tensile behavior depend mainly on the draw ratio and the DY. With growing environmental concerns and sustainability.

DY ratio is calculated as follows. Textured polyester yarn is prepared from multifilament yarn composed of a synthetic linear ethylene terephthalate polyester by draw-texturing at a draw ratio of 105 - 130X using a heat-setting temperature of about 170 - 240. DTY Draw Textured Yarn is the most used texturing process in synthetic fabrics.

What is DTY. Draw textured yarn and process Download PDF Info Publication number US3877213A. DTY maintains characters of synthetic filaments.

The inter-fiber bonds break and reform during the texturing process. Basically the draw texturing process is currently on a plateau where a signifi cant advance in process technology is diffi cult to realise and profi t margins are squeezed to the extent that draw textured yarn manufacturing can largely survive only in lower labour cost regions. These Intermingle yarns also known as interlaced yarn are the replacement for lightly twisted yarns.

The difference from FDY is that it has a false twisting process. After heating the raw material is drawn and twisteduntwisted simultaneously resulting a bulked stretchy yarn. Draw textured yarn process Nail artwork evokes Absolutely everyoneWhen you are a colorful girl then you can get up brighter color tones in your nails if you like subtle issues so certainly your mood will get on.

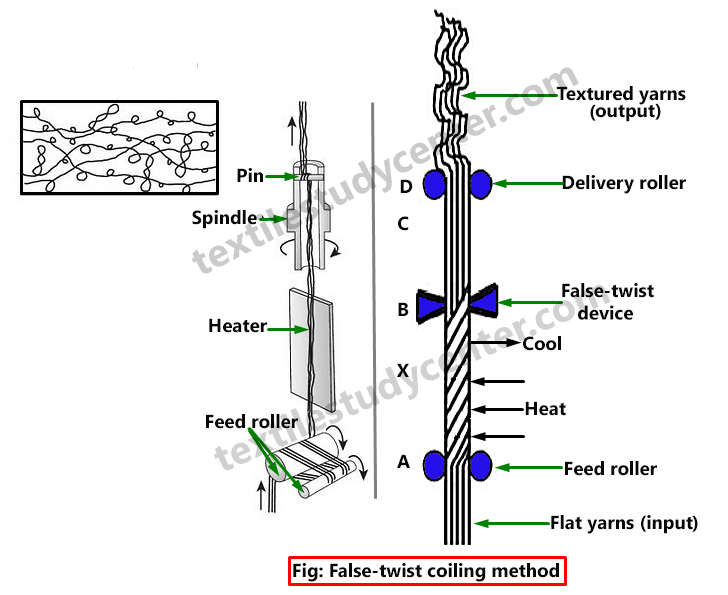

Then subjected to simultaneously false twisting friction disc device heating. The process of introducing crimp loop coils to continuous filament yarn is called Texturizing. Here the yarn is first drawn with a draw ratio of the order of 23 to 35 at a temperature of at least 50 Tg 40oC.

Setup in 2017 our division of Yarn for Technical textile Industrial end use offers high tenacity yarns which are used for a wide variety of applications. Polyester Draw Textured Yarn PDTY is obtained when the Polyester Partially Oriented Yarn POY is simultaneously twisted and drawn. A filament yarn is generally textured through three steps.

Drawn Textured Yarn DTY yarn is made when Polyester POY is simultaneously twisted drawn. Follow me see the production process. Draw ratio DY ratio and heater temperatures are the main process parameters to change 3t.

Drawn Textured Yarn DTY is obtained by processing POY. Draw Textured Yarn Process. The ratio of the disk surface speed to the yarn speed is usually referred to as DY ratio.

Spinning speeds between 3000 mmin to 4000mmin provides a partially oriented yarn which later requires draw of two during the draw texturizing. But in a relaxed state it will shrink and become fluffy. After producing the POY yarn it is going for Texturing process to give many types of effect on the yarn.

The fashion and textile industry continues to leave behind a huge environmental footprint. The properties of the textured yarn can be altered by changing these parameters 1. Two types of manmade POY can be textured- Nylon Used in manufacturing of ladies hosiery Polyester Used in.

Different yarns can be created for desired purpose by using different heating techniques. The process is called False Twist. Draw ratio DY ratio and heater temperatures are the main process parameters to change 3t.

The DTY process imparts bulk and stretch properties. It stabilizes the POY through heating and drawing. The process is particularly useful for the manufacture of.

The first step is to distort the filament in the. Feed yarn for said draw-texturing process has a a break elongation of 40 - 80 b a density of above. In our plant we declared earlier the final product of POY is to go to the Draw Textured draw Tension Draw warping.

Draw Texturing Process is discussed below. Tension twist and temperature. This process disperses curls and entangles the filaments composing the POY yarn which gives DTY a fluffy appearance and gives it the properties of both natural and synthetic fiber.

Polyester DTY Yarn has endless varieties of applications in the apparel and non-apparel industry ranging from weaving knitting of fabrics for clothes to home furnishings and seat covers. Yarns for Technical Textile. DY Circumferential speed of disks mmin.

DTY yarns are known as thread Heat set and bulky filament. We offer Draw Textured Yarns with wide denier range and in various shades to meet. DTY process is similar to perming hair.

Texturizing can be termed as the process in which loops crimps or coils are introduced into a continuous filament yarn. The process involves hot drawing twisting thermosetting and de-twisting. False-twist texturing process can be investigated based on three main parameters which are called 3t.

Such as crimp bulkiness crease etc. Drawn Textured Yarn DTY yarn is obtained when Polyester POY is simultaneously twisted drawn. After the false twisting the DTY passes through the additional heating zone to become a set-DTY.

The yarn develops a texture by twisting and drawing simultaneously using heat. This process disperses curls and entangles the filaments composing the POY yarn which gives DTY a fluffy appearance and gives it the properties of both natural and synthetic fiber. US3877213A US21894772A US3877213A US 3877213 A US3877213 A US 3877213A US 21894772 A US21894772 A US 21894772A US 3877213 A US3877213 A US 3877213A Authority US United States Prior art keywords yarn denier draw twist.

Such twisted yarn can also be heat-set to make the yarn permanently thermo-set the twist. DTY is the abbreviation of draw texturing yarn and the Chinese name is.

Textile Science Draw Textured Yarn

Sequential Texturing Polyspintex Inc

Effect Of D Y Ratio On Draw Texturing Yarn Indian Textile Journal

Drawing Texturing Intermingling And Heat Setting Process

Production Principle Of Mechanical Crimp Texturizing Download Scientific Diagram

0 comments

Post a Comment